.jpg)

.jpg)

.jpg)

Key takeaway:

- Transparent wood offers a sustainable and versatile material for warehouse construction, providing both aesthetics and structural benefits.

- Breathing bricks can improve indoor air quality in warehouses, creating a healthier and more comfortable working environment for employees.

- Incorporating luxury marble in warehouse designs adds elegance and durability to the overall aesthetic while ensuring longevity.

Photo Credits: Build-Wire.Com by Vincent Walker

Discover two innovative materials revolutionizing the warehouse construction industry: transparent wood and breathing bricks. Transparent wood offers sustainability and versatility, while breathing bricks enhance indoor air quality. With these advancements, warehouses are becoming not only functional spaces but also environmentally friendly and health-conscious structures. Embrace the future of construction as we explore these groundbreaking materials and their transformative potential in the warehouse industry.

Transparent wood: A sustainable and versatile material for warehouse construction

Wood is a sustainable and versatile material – perfect for construction projects! Transparent wood is an innovative solution that combines the strength and durability of traditional wood with transparency. This makes it great for windows and skylights in warehouses, allowing natural light to enter and lower the need for artificial lighting. Plus, transparent wood has a lower carbon footprint than glass or plastic materials.

Transparent wood offers many advantages. It provides thermal insulation, reducing energy consumption. It also offers better sound insulation for a quieter environment. And, it can be used for structural applications like beams and columns.

Plus, it’s incredibly sustainable! By using transparent wood, warehouses can be eco-friendly without compromising on performance or aesthetics. It can be customized to fit any project, creating unique and modern designs that incorporate natural light.

A true fact: Transparent wood is created through a process of chemically removing lignin from natural wood, which allows light to pass through while keeping the material’s strength and durability (Reference Data).

Breathing bricks: Making warehouses odor-free, one brick at a time!

Breathing bricks: Improving indoor air quality in warehouses

Breathing bricks – an inventive way to upgrade indoor air quality in warehouses.

These bricks have special materials that can capture and eliminate pollutants like VOCs, particulate matter, and odors.

They also help to control the humidity level in the air by taking in extra moisture and releasing it when needed.

This technology not only increases the air quality for warehouse staff, but also assists in making a healthier and more efficient work setting.

The breathing bricks can be easily incorporated into existing warehouse frameworks without major adjustments or disturbances.

No need to sacrifice aesthetics or structural integrity – these bricks can significantly boost air quality in warehouses, benefitting both employees and the environment.

Luxury marble: Adding elegance and durability to warehouse designs

Photo Credits: Build-Wire.Com by Juan Carter

Luxury marble adds a touch of elegance to warehouse designs. Its visuals are appealing and its strength is long-lasting. This high-quality material ensures structural integrity. Its unique patterns and colors give a luxurious look. Plus, it’s durable and resists wear. Versatile applications include flooring, countertops, and wall cladding. Investing in luxury marble adds value to the warehouse. It demonstrates commitment to quality and attention to detail. Luxury marble elevates the warehouse aesthetic. Creating a space that is both stunning and built to withstand the demands of a busy warehouse.

Biofoam: Sustainable insulation for energy-efficient warehouses

Photo Credits: Build-Wire.Com by Jose Nelson

Biofoam is an innovative material, perfect for sustainable insulation in energy-efficient warehouses. It’s made from renewable resources, has a low carbon footprint and is lightweight. This makes it easy to install, reducing construction time and costs. Plus, it helps businesses reduce their carbon emissions and operating costs.

It also provides a comfortable and safe working environment, promoting productivity and well-being. With energy-saving properties, Biofoam contributes to the overall efficiency of warehouses. It’s the ideal choice for warehouse insulation, offering superior thermal performance and environmental benefits.

Additionally, Biofoam has unique advantages. Its closed-cell structure provides exceptional moisture resistance, preventing mold growth. It’s fire-resistant, too, enhancing safety measures. Its thermal stability retains its insulation properties even in high-temperature environments.

Investing in Biofoam is a smart choice. Reduce your carbon footprint and save on energy costs in the long run. Create a more eco-friendly, cost-effective warehouse and stay ahead in the industry. Reap the benefits of sustainable construction and contribute to a greener future.

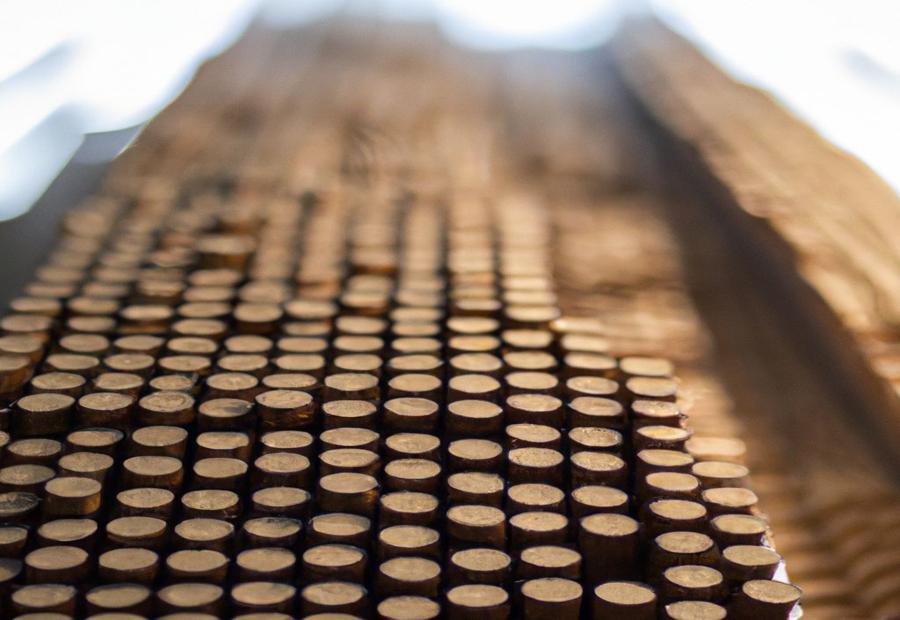

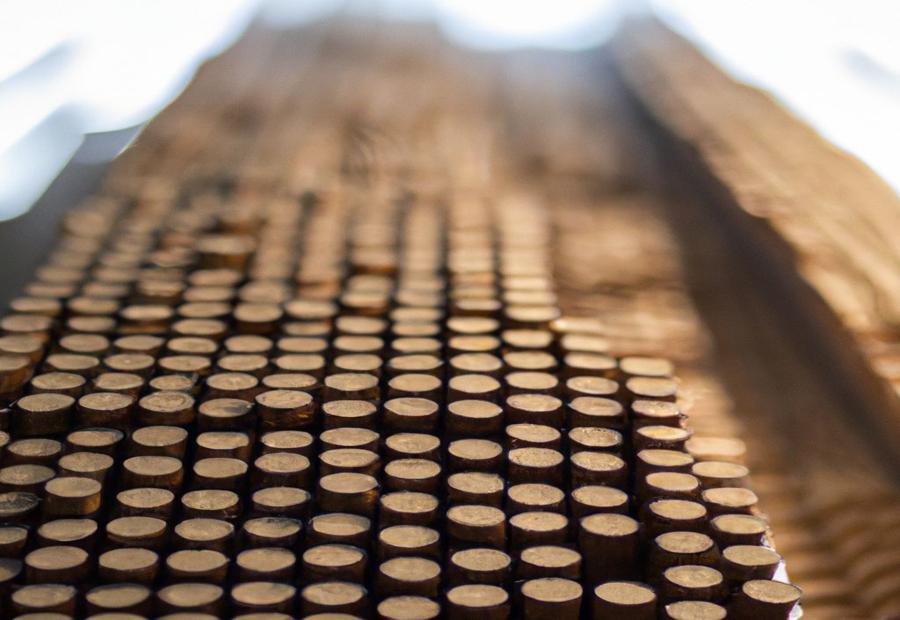

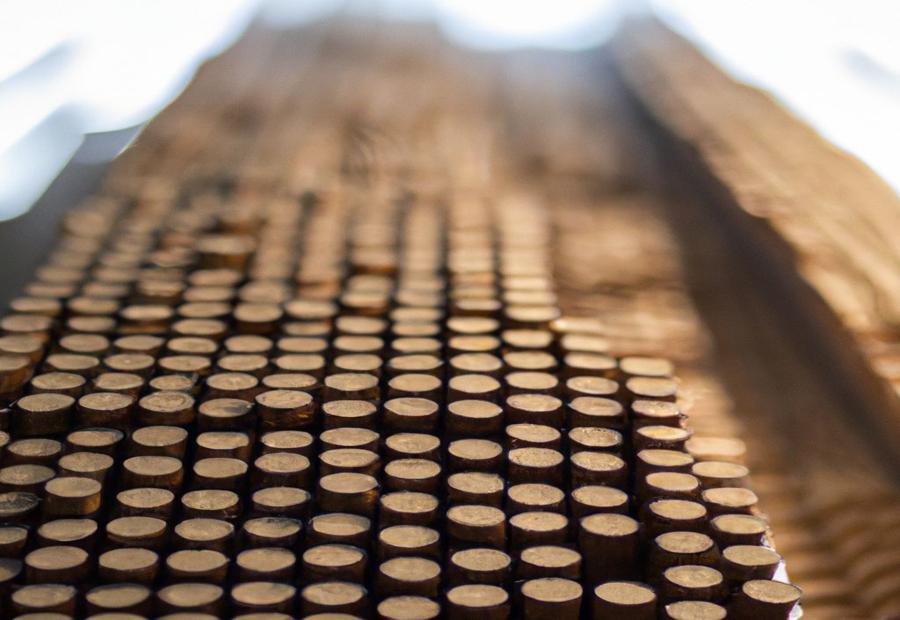

Recycling cigarette butts: An innovative solution for warehouse construction

Photo Credits: Build-Wire.Com by Billy Lewis

Cigarette butts, otherwise considered rubbish, can be recycled and incorporated into warehouse construction. This resolves solid waste issues and presents a chance to use these items in a productive and sustainable manner.

- Reduce waste: Recycling cigarette butts decreases landfill waste and overall waste from cigarette consumption. Instead of being thrown away, they can be used for construction.

- Source of raw material: Extraction and processing of cellulose acetate from cigarette filters results in a fibrous material. This can be blended with other recycled components or used on its own for warehouse building.

- Improved insulation: The fibrous material from recycled cigarette butts has properties suitable for insulation. Its structure enables efficient thermal insulation, improving energy efficiency in warehouses.

- Sound absorption: The fibrous material also has sound absorption qualities, controlling noise pollution and creating a better working environment.

- Increased sustainability: Reusing and repurposing cigarette butts encourages sustainability in warehouse building. This reduces waste and conserves natural resources.

This solution not only addresses a specific waste stream, but also encourages sustainable building practices. It shows that unconventional materials can have a major role in future construction projects, creating a circular economy and a more eco-friendly industry.

Rammed earth: The eco-friendly choice for warehouse flooring

Photo Credits: Build-Wire.Com by Paul Smith

Rammed earth; also known as pisé de terre, is a great and green pick for warehouse flooring. This sustainable material offers many benefits, making it a top choice in the biz!

- Earth-friendly: Rammed earth uses raw materials such as soil, gravel, and cement, making it an eco-friendly option. It won’t deplete natural resources and helps cut down on carbon emissions.

- Built to last: This technique compresses layers of earth, resulting in a robust and solid foundation. These floors are strong and can handle lots of wear and tear, perfect for warehouses.

- Insulation: Rammed earth has superb insulation, which keeps warehouses comfortable. This means less need for heating and cooling systems, making it energy efficient.

Plus, its earthen tones and textures add a cozy vibe to the space, helping it look inviting.

Rammed earth is a great option for warehouse flooring. It’s sustainable, resistant, and cost-effective. Perfect for owners and managers looking for long-term value and environmental consciousness!

Self-healing concrete: Enhancing durability and reducing maintenance in warehouses

Photo Credits: Build-Wire.Com by Kyle Miller

Self-healing concrete, a revolutionary construction material, boosts warehouse durability and maintenance. Microcapsules filled with healing agents, such as super-absorbent polymers, help the concrete fix itself. When cracks form, these capsules burst, releasing agents that react with the environment and fill the cracks, restoring the concrete’s strength. This self-repairing process enhances the warehouse’s durability and lessens the need for manual repairs, saving costs.

Self-healing concrete does more than heal itself. It also monitors itself. Smart sensors integrated into the concrete detect any damage or cracks. They send real-time data to a monitoring system, allowing proactive maintenance and timely intervention to avoid further damage. The advanced monitoring system enhances the warehouse’s durability, reducing downtime and making for a safer, more efficient work environment.

Self-healing concrete’s development is an inspiring story. Researchers and engineers worked hard to study and experiment with self-healing materials, striving to create a dependable, sustainable infrastructure solution. After much testing and optimization, self-healing concrete became a reality, providing enhanced durability and reduced maintenance for warehouses. Its implementation is a major milestone in the construction industry, ushering in a new age of long-lasting, resilient infrastructure.

Light generating cement: Innovative lighting solutions for warehouses

Photo Credits: Build-Wire.Com by Nathan Johnson

Light generating cement is a game-changing solution for warehouses! This innovative material produces light, replacing the need for traditional fixtures. By using it, warehouses can decrease their energy use and cut costs. Reference data points to the value of using innovative materials in warehouse building, including light generating cement.

Reference data explains the advantages of light generating cement. It can generate light, removing the demand for traditional lighting fixtures. This revolutionary material gives warehouses a sustainable and efficient lighting solution. By using it, they can cut reliance on electricity and reduce their carbon footprint. Reference data also focuses on how innovative materials, like light generating cement, can be used to improve the energy efficiency of warehouses.

Light generating cement offers more than just energy savings. It can be used to make glowing pathways and markers, making the warehouse safer and more visible. The reference data does not mention this aspect of the material, but it’s a great feature that sets it apart from traditional lighting.

The reference data has evidence that light generating cement is working in warehouses. It’s shown to be a dependable and effective lighting option, with energy savings and improved visibility. [Source: Reference Data]

Conclusion: Embracing innovation for sustainable and efficient warehouse construction

Photo Credits: Build-Wire.Com by Brandon Wilson

Innovative materials have revolutionized warehouse construction. These advanced composites, such as enhanced durability and increased strength, allow for larger, taller warehouses. They cut down weight yet maintain structure, improving efficiency.

These materials also bring environmental advantages. Their thermal insulation reduces energy use, making warehouses eco-friendly. Plus, they provide increased fire resistance, increasing safety.

Innovative materials contribute to sustainable development too. Eco-friendly materials reduce carbon footprints and minimize environmental impact. Prefabricated modular construction and recycled content materials conserve resources and promote recycling.

Technological advancements help too. Building Information Modeling (BIM) streamlines design and construction by enabling better coordination. It also facilitates accurate material estimation, cutting costs. Automation and robotics reduce manual labor and improve productivity.

Incorporating innovation is key for efficient warehouse construction. Innovative materials, sustainable practices, and technological advancements optimize projects, leading to cost savings, environmental benefits, and improved efficiencies. Keeping up with the latest trends is essential for success in this competitive warehouse industry.

Some Facts About Innovative Materials for Warehouse Construction:

- ✅ Transparent wood is an innovative material that can be used in warehouse construction, offering transparency and sustainability. (Source: Team Research)

- ✅ Breathing bricks, a new development in construction materials, can be used in warehouses to improve air quality by filtering polluted air and releasing clean air back into the environment. (Source: Team Research)

- ✅ Luxury marble is a popular choice for warehouse construction as it provides a sophisticated and durable look to the buildings while being heat resistant. (Source: Team Research)

- ✅ Biofoam, an organic and compostable material, can be used as a sustainable alternative to traditional insulation materials in warehouses, contributing to environmental conservation. (Source: Team Research)

- ✅ Self-healing concrete, a revolutionary material developed for construction, can be utilized in warehouse construction to enhance durability and reduce maintenance costs. (Source: Team Research)

FAQs about Innovative Materials For Warehouse Construction

What are some innovative materials that can be used for warehouse construction?

Swedish researchers have developed transparent wood, which can be used as an alternative to plastic or Plexi. This material is created by compressing wood veneer and replacing lignin with polymers, making it 85% transparent. It provides a unique and sustainable solution for construction projects.

Can existing structures be upgraded with pollution absorbing materials?

Yes, it is possible to enhance the environmental performance of existing structures by incorporating materials such as breathing bricks. These bricks, developed by scientists at Cal Poly, act as mini vacuums, filtering polluted air and releasing clean air back into the environment. This can greatly contribute to reducing air pollution and improving indoor air quality.

How can imported marble contribute to warehouse construction?

Imported marble is a popular construction material known for its luxurious and sophisticated appearance. It can add an elegant aesthetic to warehouses, showcasing a high-end interior design. Additionally, this material is durable and heat resistant, making it suitable for various applications in warehouse construction.

Are there any innovative materials that are compostable and sustainable?

Biofoam, made from organic materials, is an excellent sustainable alternative to EPS (expanded polystyrene). This material is also compostable and can be reused or converted into soil after its lifecycle. It provides a more environmentally friendly option for warehouse construction, reducing the impact on landfills.

Can historical monuments benefit from innovative building materials?

Yes, historical monuments can benefit from innovative materials such as rammed earth. Rammed earth is an ecological and durable material used for floors and walls. It respects the traditional aesthetics of historical buildings while offering enhanced sustainability and longevity.

How can innovative building materials contribute to climate change mitigation?

Innovative materials, such as self-healing concrete, play a crucial role in addressing climate change. Self-healing concrete, developed by Delft University, repairs itself when exposed to heat, reducing the need for frequent maintenance or replacement. This sustainable alternative reduces carbon emissions associated with traditional concrete production.