In the realm of industrial workshops, the foundation upon which these structures are built holds crucial significance. The proper selection and implementation of the appropriate foundation type are imperative to ensure the integrity and stability of these facilities. This article explores the various types of foundations commonly used in industrial workshops, ranging from shallow foundations to deep foundations, while also delving into the key considerations that need to be taken into account. By understanding the different foundation options available and the factors that must be considered, professionals involved in industrial workshop construction can make informed decisions that will ultimately contribute to the overall success and longevity of these vital structures.

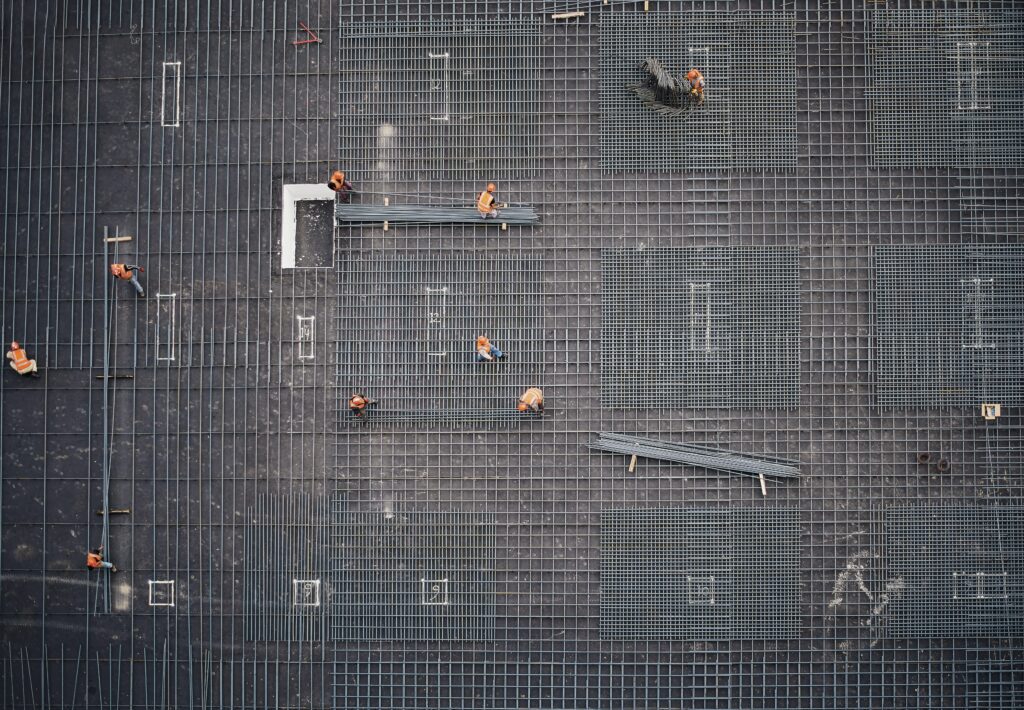

This image is property of images.unsplash.com.

Understanding Industrial Workshop Foundations

Industrial workshop foundations are a crucial aspect of any industrial facility as they provide the necessary support and stability for the structures and equipment present in the workshop. These foundations play a fundamental role in ensuring the overall operational efficiency and safety of the workshop. Hence, understanding the different types of workshop foundations, their benefits, and the key considerations involved in choosing the right foundation is of utmost importance for industrial stakeholders.

Basic Importance of Workshop Foundations

Workshop foundations serve as the base upon which the entire workshop structure is built, making them an essential component for the stability and longevity of the facility. The foundation distributes the weight of the workshop evenly, minimizing the risk of settlement or structural failure. Furthermore, it provides a solid platform for the installation and operation of heavy machinery and equipment, ensuring smooth and safe industrial operations. Without a solid foundation, the workshop’s functionality and safety would be compromised.

Role in Industrial Function and Safety

The foundation of an industrial workshop is instrumental in maintaining the overall function and safety of the facility. A well-designed and properly constructed foundation ensures that the workshop structure can withstand the dynamic loads and vibrations generated by heavy machinery, reducing the risk of structural damage or collapse. Additionally, an adequately designed foundation helps to prevent ground movements, such as differential settlement or soil erosion, which may compromise the stability of the workshop. Thus, the foundation acts as a crucial safeguard for the workers and machinery within the workshop, promoting a safe working environment.

Necessity for Structural Integrity

Structural integrity is paramount when it comes to industrial workshop foundations. The foundation must be able to withstand the various forces and stresses imposed on it, such as vertical loads, lateral loads, and dynamic loads. It is imperative that the foundation is designed and constructed in such a way that it can effectively bear the weight of the workshop and any additional loads imposed on it. A structurally sound foundation ensures the long-term stability and reliability of the workshop, preventing the risk of structural failure that may have severe consequences.

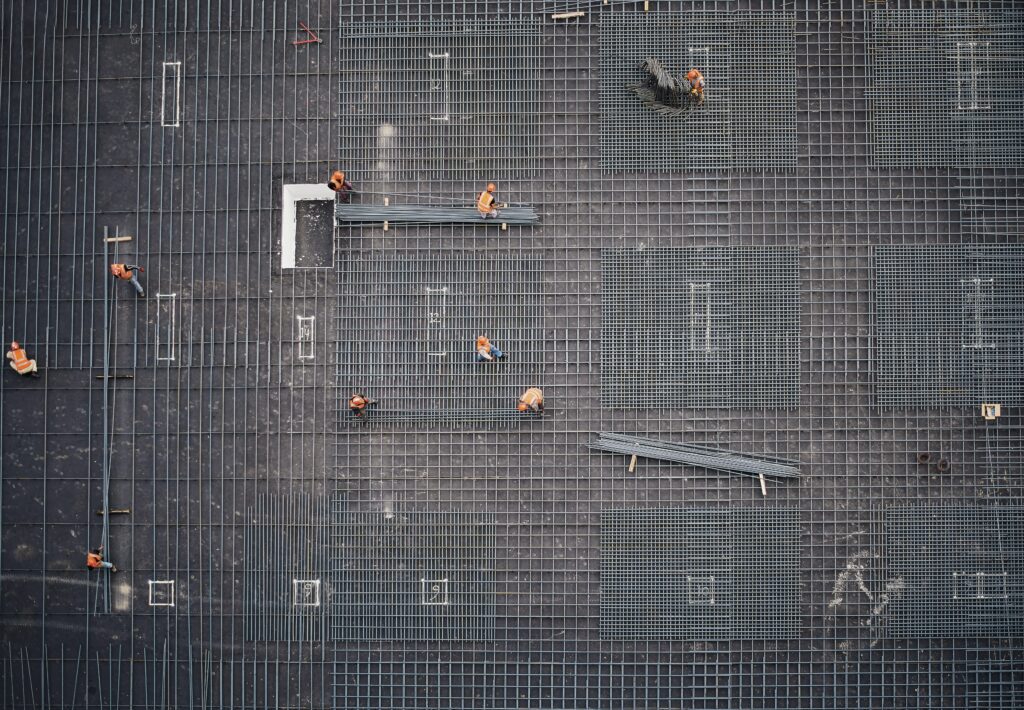

This image is property of images.unsplash.com.

Types of Industrial Workshop Foundations

There are several types of foundations commonly used in industrial workshops, each with its own set of advantages and disadvantages. The choice of foundation depends on various factors such as the soil conditions, site location, load-bearing requirements, and budget constraints. The four main types of industrial workshop foundations are slab-on-grade foundations, full basement foundations, pile foundations, and caisson foundations.

Slab-On-Grade Foundations

A slab-on-grade foundation, also known as a floating slab or simply a slab foundation, is a type of foundation that consists of a single layer of concrete poured directly onto the ground surface. This method eliminates the need for extensive excavation and provides a level and durable base for the workshop floor. Slab-on-grade foundations are commonly used in areas with stable soil conditions and a low water table.

One of the main benefits of slab-on-grade foundations is their cost-effectiveness and ease of construction. This type of foundation requires less labor, materials, and time compared to other foundation types, making it an attractive choice for industrial workshops with limited budgets. Additionally, slab-on-grade foundations offer a smooth and level working surface, making them ideal for workshops that require the movement of heavy equipment and machinery. However, slab-on-grade foundations may not be suitable for areas with expansive soils or high water tables, as they are more prone to cracking and moisture-related issues.

Full Basement Foundations

Full basement foundations are characterized by the presence of a below-grade space that spans the entire footprint of the workshop. These foundations provide additional usable space below the ground level, which can be utilized for storage or other purposes. Full basement foundations are typically constructed in areas with stable soil conditions and a favorable water table.

The main advantage of full basement foundations is the extra space they offer, which can be utilized for various purposes such as storage, utility rooms, or even additional workshop areas. This type of foundation also provides increased protection against the elements, as the basement is partially or fully below the ground level. However, full basement foundations are generally more expensive and time-consuming to construct compared to other foundation types. They also require careful waterproofing measures to prevent moisture-related issues.

Pile Foundations

Pile foundations are deep foundation systems that are used when the soil near the surface is not able to support the load of the workshop. Piles, which are long, slender columns made of materials such as steel or concrete, are driven or drilled into the ground until they reach a stable soil or rock layer. The weight of the workshop is then transferred to these piles, providing the necessary support and stability.

Pile foundations offer several advantages, such as increased load-bearing capacity, enhanced resistance to soil movement, and the ability to be installed in a variety of soil conditions. They are particularly suitable for areas with poor soil conditions, high water tables, or in regions prone to seismic activity. However, the installation of pile foundations can be costly and time-consuming, as it requires specialized equipment and expertise.

Caisson Foundations

Caisson foundations, also known as drilled shaft foundations or pier foundations, are deep foundation systems that are typically used when the load-bearing capacity of the soil near the surface is insufficient. Caissons are constructed by excavating a hole into the ground and filling it with reinforced concrete or steel. The caissons serve as deep columns that transfer the load of the workshop to a suitable soil or rock layer.

One of the main benefits of caisson foundations is their ability to provide high load-bearing capacity, making them suitable for industrial workshops with heavy machinery and equipment. Caissons are also resistant to lateral forces, which is advantageous in areas prone to high winds or seismic activity. However, caisson foundations require extensive excavation and specialized equipment, making them more expensive to construct compared to other foundation types.

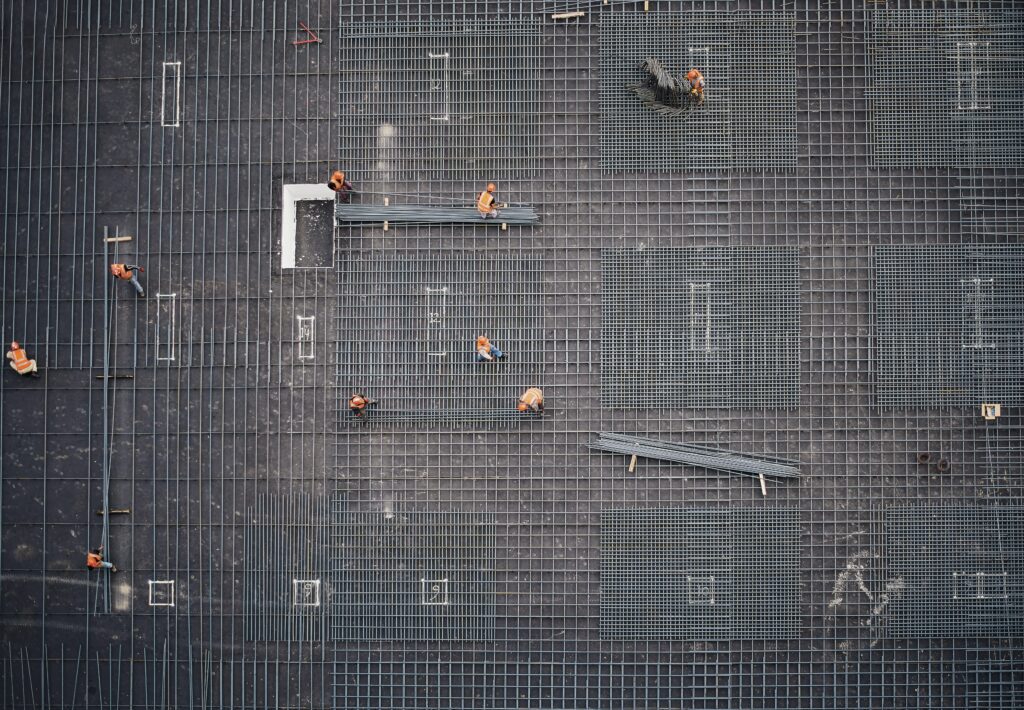

This image is property of images.unsplash.com.

Slab-On-Grade Foundations

Defining Slab-On-Grade Foundation

A slab-on-grade foundation, also commonly referred to as a floating slab or a slab foundation, is a type of foundation that is directly placed on the ground surface without any basement or crawl space beneath it. This type of foundation consists of a single layer of concrete that is poured directly onto a prepared soil subfloor.

Benefits and Disadvantages

Slab-on-grade foundations offer several benefits that make them a popular choice for industrial workshops. One of the significant advantages is their cost-effectiveness. Slab-on-grade foundations require less excavation and materials compared to other types of foundations, resulting in lower construction costs. Additionally, the simplicity of construction and reduced labor requirements can lead to faster project completion times.

The even and level surface provided by slab-on-grade foundations is another advantage, particularly for workshops that need the movement of heavy machinery or equipment. The absence of a crawl space or basement in slab-on-grade foundations also means no moisture-related issues typically associated with such spaces, such as mold or humidity concerns.

However, slab-on-grade foundations may not be suitable for all workshop environments. They are more susceptible to moisture-related problems if not adequately sealed and insulated. Additionally, this type of foundation may not be ideal for areas with unstable soil conditions or areas prone to freezing temperatures, as it does not provide the same level of protection against ground movement or frost heaving as other foundation types.

Ideal Usage Scenarios

Slab-on-grade foundations are commonly used in industrial workshops that have stable soil conditions and a low water table. They are particularly suitable for workshops that do not require additional below-grade space, such as storage or utility rooms. Slab-on-grade foundations are also well-suited for workshops with limited budgets, as they offer a cost-effective solution without compromising the overall performance and stability of the structure.